You are here: Beltron GmbH | Products | Beltrotherm dryer concept | Continous belt dryer for evaporation and drying after wet lacquer coating

Beltrotherm

CONTINUOUS BELT DRYER FOR EVAPORATION

AND DRYING AFTER WET LACQUER COATING

BELTROTHERM CONTINUOUS BELT DRYER FOR EVAPORATION AND DRYING AFTER WET LACQUER COATING

All colors, lacquers and products applied by wet coating process are dried in horizontal continuous process single or double-sided.

Type of heat sources, air flow, temperature, evaporation and drying times to be adapted to the requirements. The resulting temperature profiles and belt speed is stored in the PLC - control. For the one-sided process there are flat belt transport systems, for double-sided process V-belt transport systems available.

Our Technology and Sales-Partner in Electronic Industry

ahk GmbH · Gewerbering 8 - 13 · 74193 Schwaigern · Germany

Tel.: +49 (0)7138 - 81274-0 · Fax: +49 (0)7138 - 81274-10

Email: info@ahk-service.de · Internet: www.ahk-service.de

Details of our high-performance

Thermo Dryer Beltrotherm:

+ Ballast ( 100% and 50% adjustable)

+ UV lamp with or without

pneumatic shutter

+ Air-coded housing with

aluminium reflector

Details BELTRON

Thermo Dryer

BeLtrotherm Details of our

high-performance

Thermo Dryer Beltrotherm

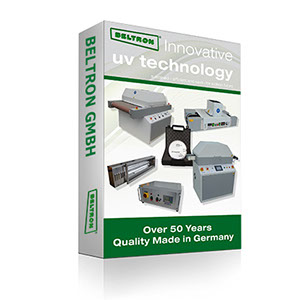

Beltron Thermo Dryer Beltrotherm have many key benefits for you and your production, take advantage of our quality benefits:

+ 60 years quality "Made in Germany"

+ Innovative UV technology

+ Complete, even drying

+ Very short drying times

+ Sustainable energy-saving systems

+ Further processing possible immediately

+ Highly scratch-resistant and shiny

+ Durable & increased chemical resistance

BELTRON Thermo Dryer Beltrotherm

are used successfully in:

+ printing industry

+ electronic industry

+ plastic industry

+ textile industry

+ packaging industry

+ glass industry

advantage BELTRON

Thermo Dryer

Beltrotherm Advantages of our

high-performance

Thermo Dryer Beltrotherm

applications BELTRON

Thermo Dryer

BeLtrotherm Uses of our

high-performance

Thermo Dryer Beltrotherm

The Thermo-Dryer BELTROTHERM are used successfully in:

These are just a few examples from the various partner portfolio of Beltron.

- printing industry

- electronic industry

- plastic industry

- textile industry

- packaging industry

- automotive industry

- glass industry

Working widths: 610 mm / 24" or 760 mm / 30"

Belt speed: adjustable

Tack drying soldermask: 0,5 - 50,0 m/min.

Curing soldermask: 0,2 - 2,0 m/min.

Curing paste: 0,5 - 5,0 m/min.

Temperature range: RT - 250°C

Electrical connection: 400 V 3/N/PE 50 Hz

Connecting power per module: 9,3 kW / 18,6 kW

Working power per module: 4,6 kW / 9,3 kW

Supply air, exhaust air per Module 100 - 300 m³/h

Module length: 1000 mm

Module width: 1000 mm

Module height: 1200 mm

Available modules:

tranquilizers module

Abdunstmodul

heating module

cooling module

Inlet / outlet, various

PLC control: In the mobile console with touch-screen screen

Information

Beltrotherm

Advice to Thermo dryer Beltrotherm:

Phone: +49 6074 - 89199-0 or E-Mail: info@beltron.de

Contactform - Thermo dryer Beltrotherm